RENEWAL OF OLD COATINGS USING PETROLATUM SYSTEMS

KEBU PBM 01 System

ALL SURFACES

Coating system for buried pipelines compliant with ISO 21809-3 standard and GRTgaz SG0130 specification, HR usage category

solvent-free

minimal surface preparation

easy implementation

applicable at all temperatures and hygrometries

COMPOSITION

KEBU Primer: Vaseline-based paste, solvent-free, applicable by hand or brush

KEBU Tape: Vaseline-based anti-corrosion tape, applicable by hand

KEBULEN B120C/CF tape: butyl rubber and polyethylene based tape, applicable by hand or machine.

The components of the KEBU PMB-01 system are not classified as hazardous products and can be stored without limitation over time, provided that the storage conditions are respected.

PRINCIPLES OF IMPLEMENTATION

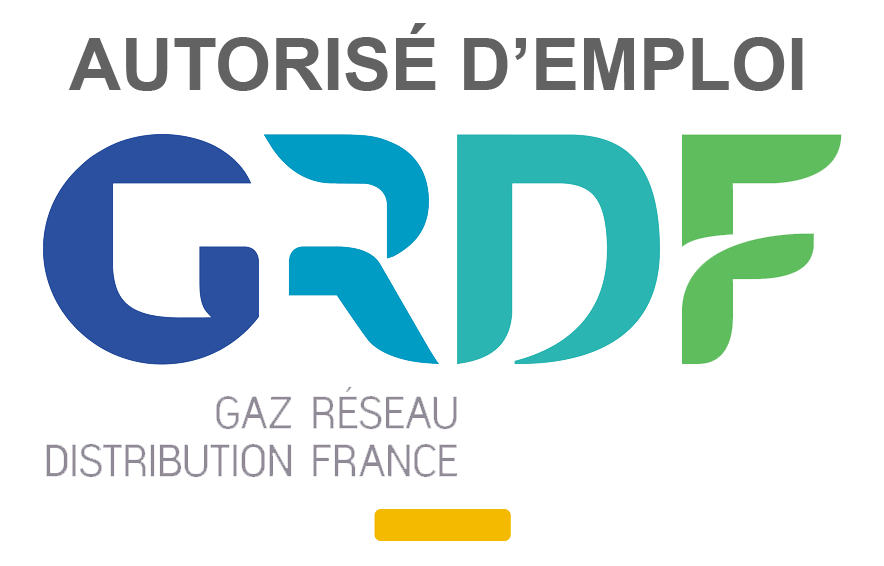

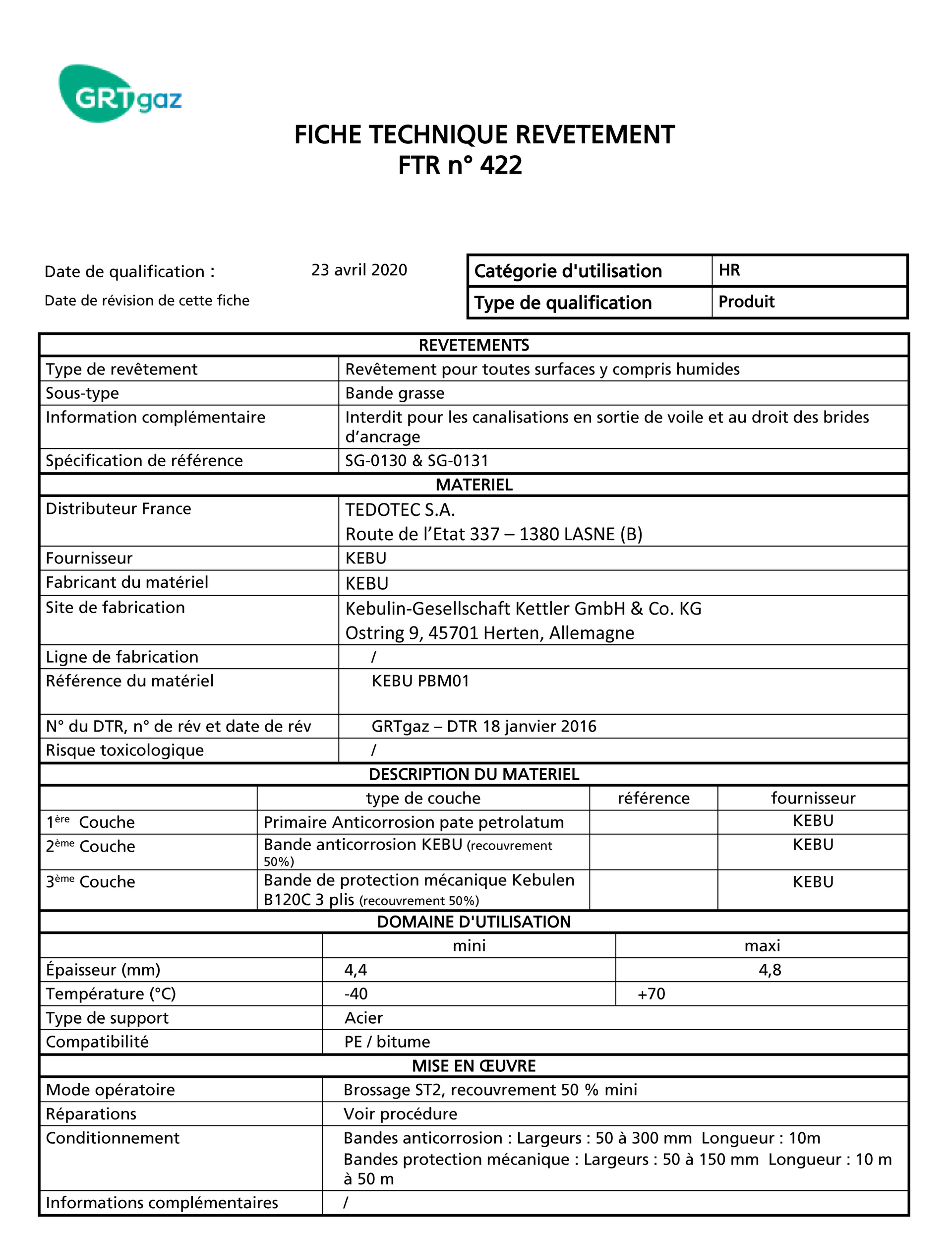

Surface preparation

The surface can be cleaned by mechanical or manual brushing.

Care should be taken to remove old non-adherent coatings, dust and other dirt, non-adherent rust and generally any particles likely to end up between the surface of the metal and the coating system.

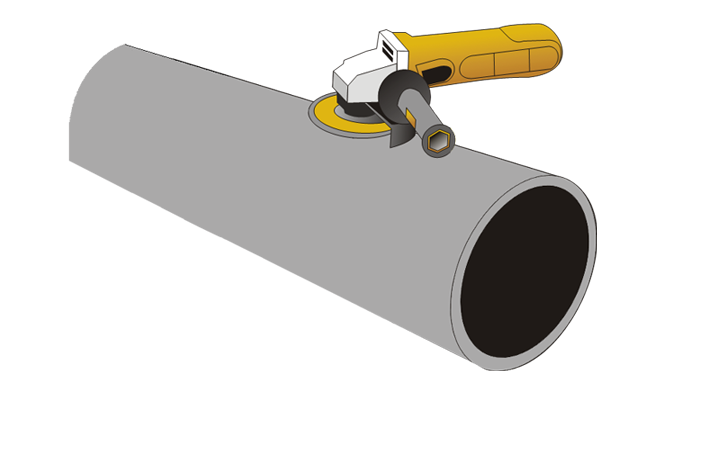

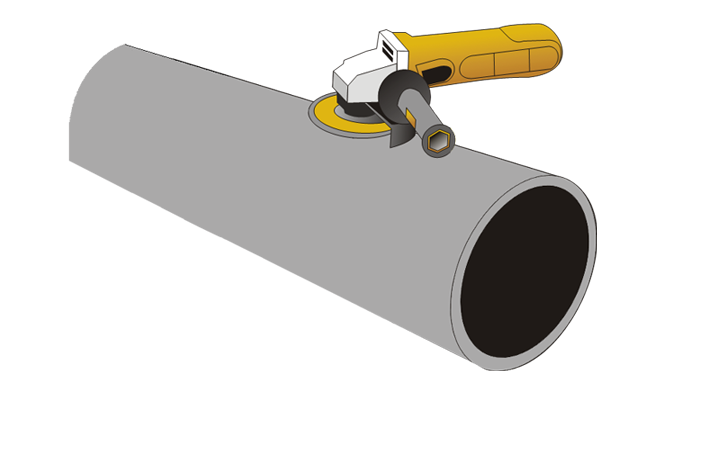

Step 1: Application of KEBU primer paste

The paste is applied by hand or with a brush, depending on its consistency, which depends on the temperature.

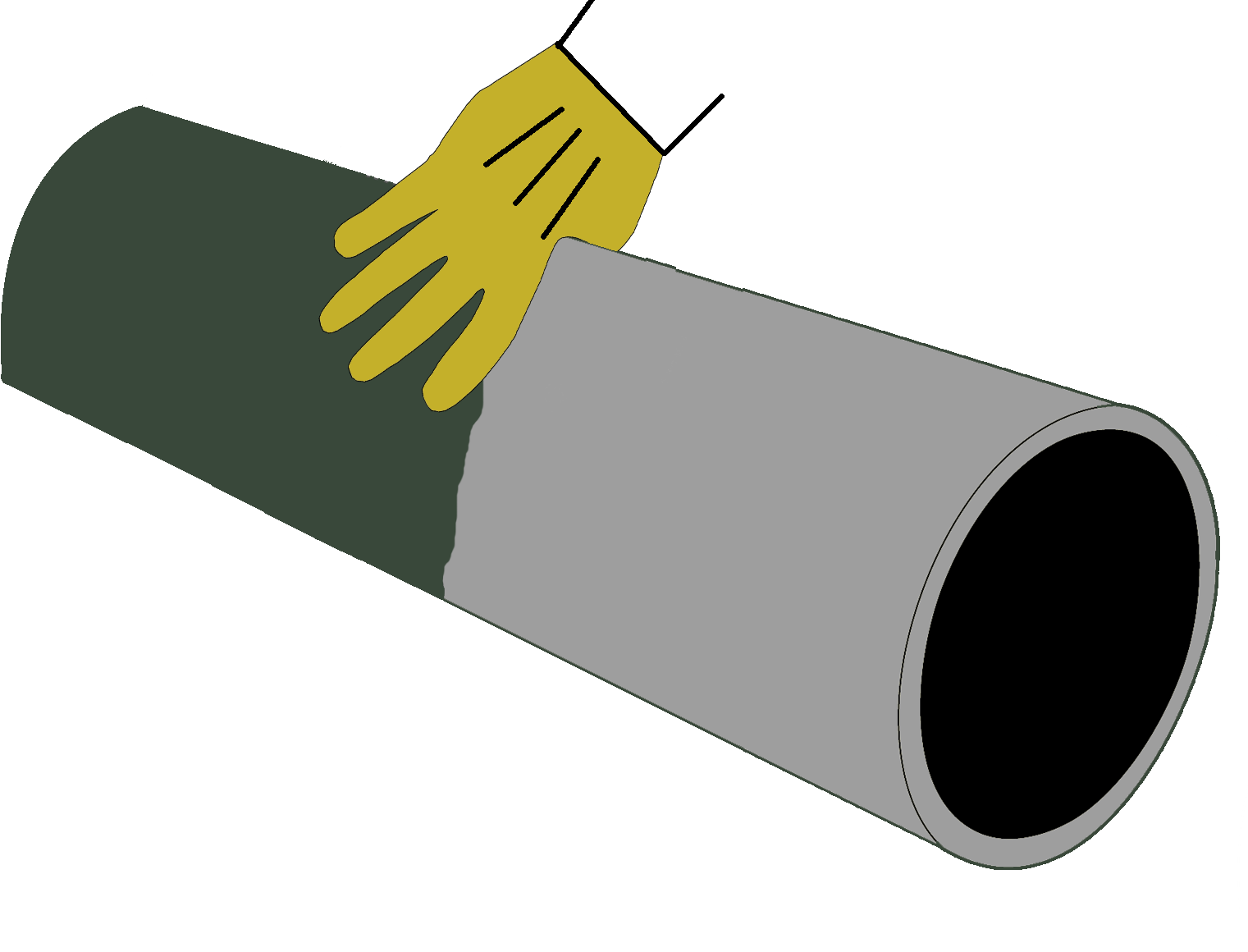

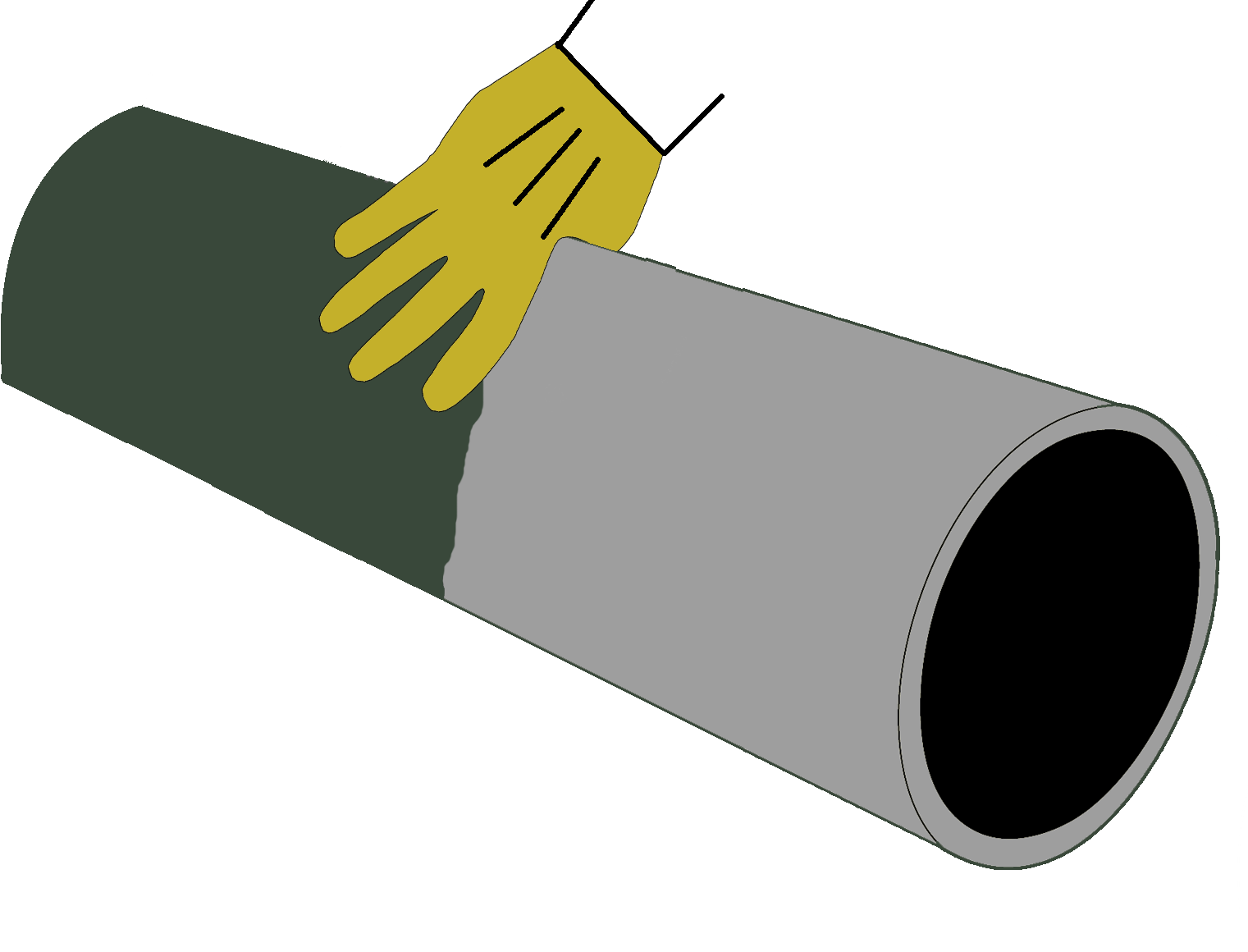

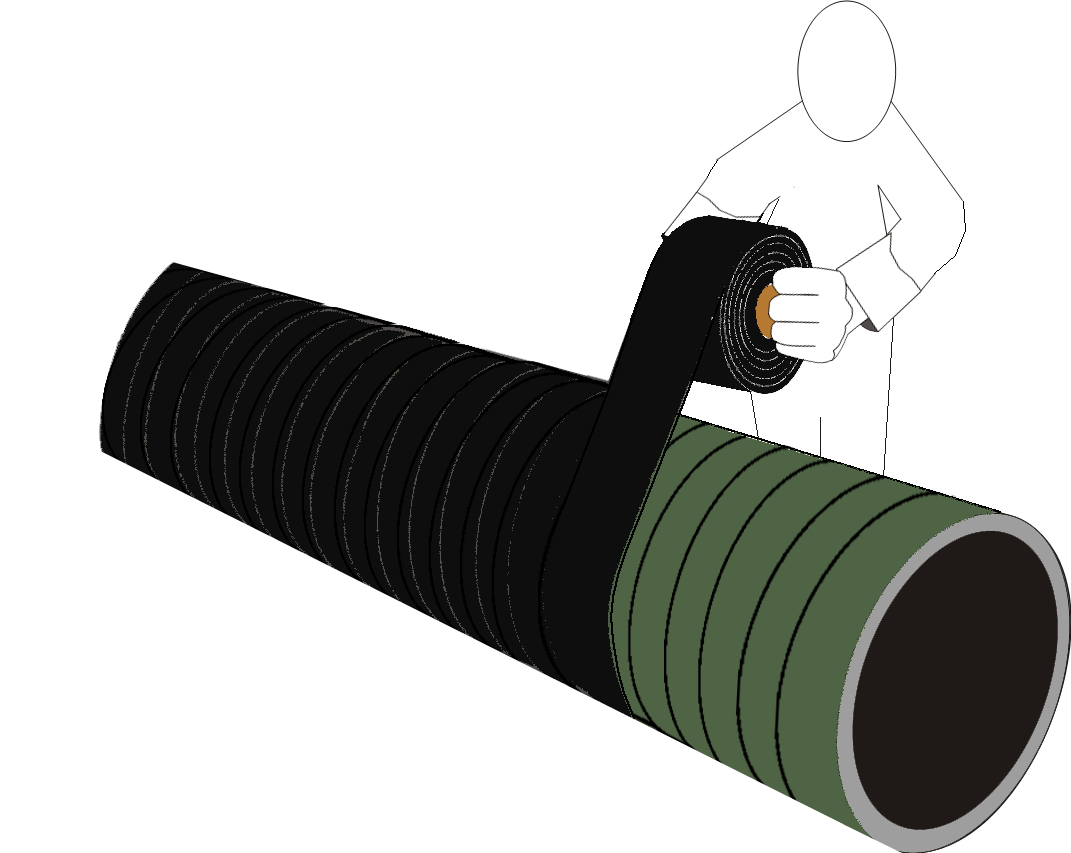

Step 2: Application of KEBU anti-corrosion tape

KEBU anti-corrosion tape is applied in a spiral, under slight tension (the tape is not elastic), with a minimum overlap of 50%.

Care should be taken to carefully smooth the strip after application, to eliminate any air bubbles and to close the coils properly.

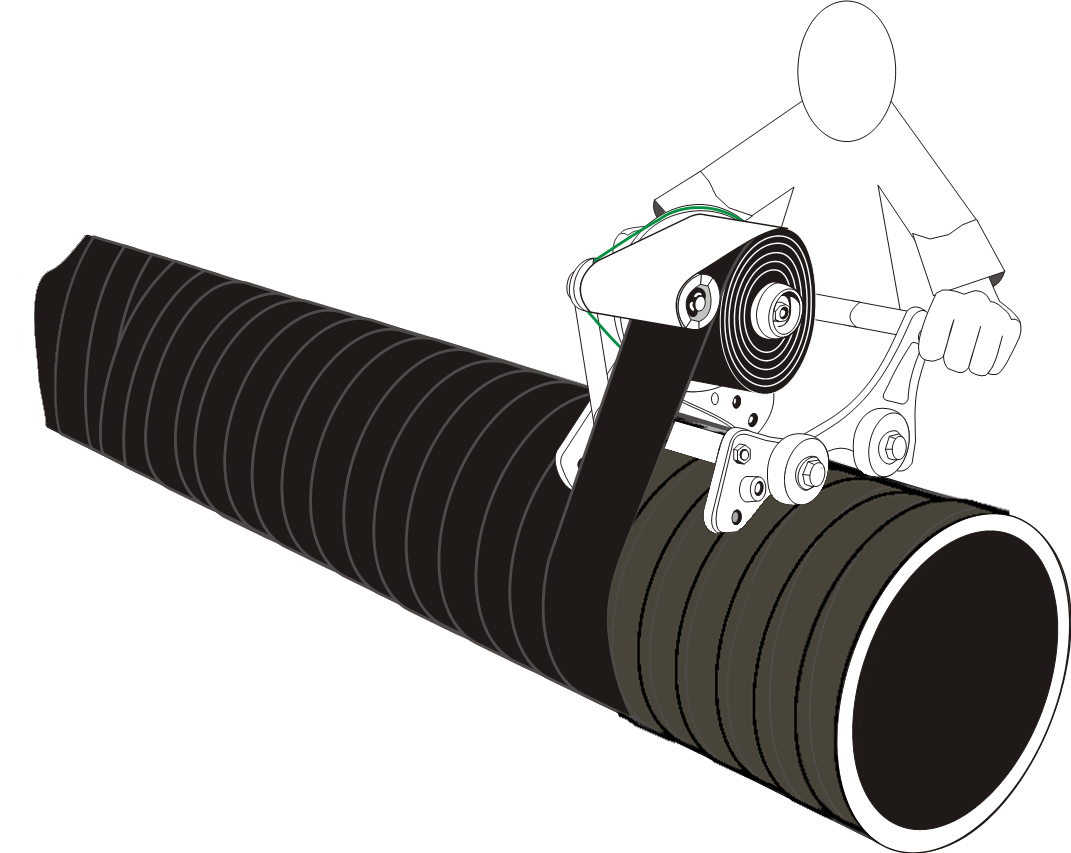

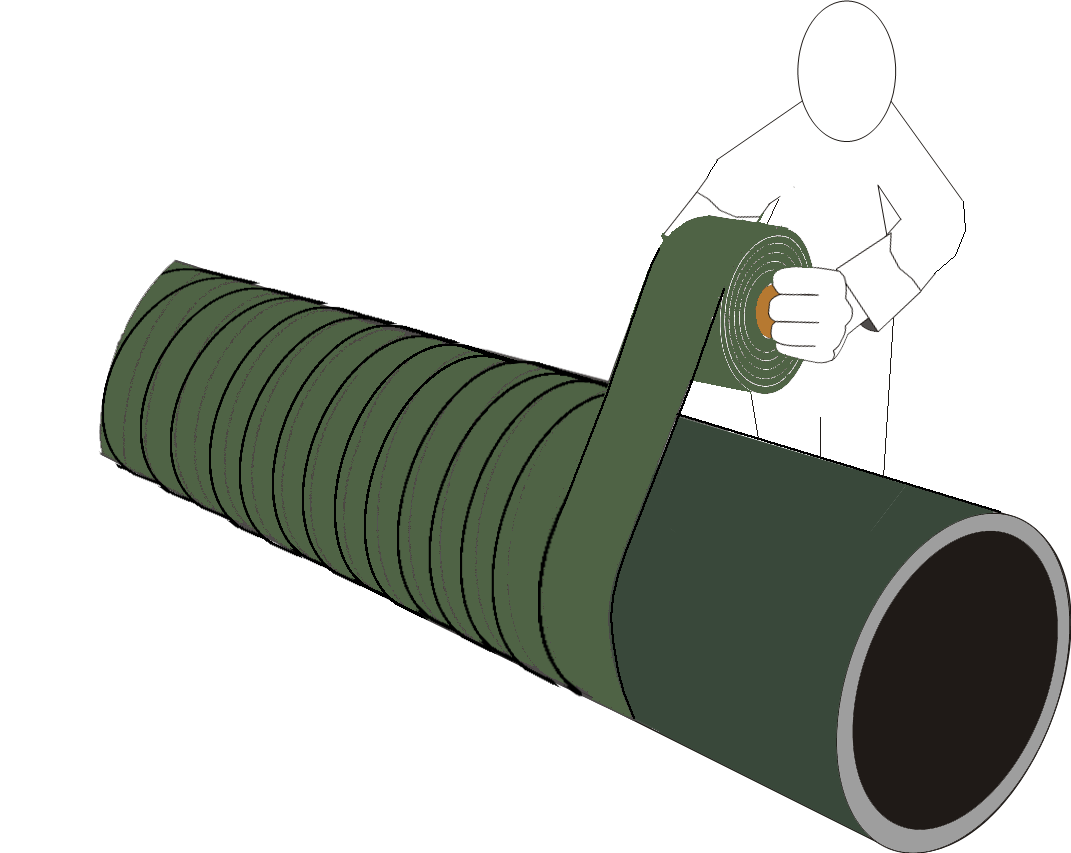

Step 3: Application of KEBULEN B120 C mechanical protection strip

The mechanical protection strip is applied under tension, either manually or using a KEBUMAT coating machine, with a 50% overlap. The start of the coating is done if possible slightly offset from the KEBU anti-corrosion strip. The KEBULEN B120 C self-amalgamating strip is provided with an interlayer that is removed as the coating progresses.

If using a machine, it is recommended to first apply a thin plastic film to avoid dirtying the wheels.

TEDO PBM 01 System

ALL SURFACES

SYSTEME AGREE

Coating system for buried pipelines compliant with ISO 21809-3

solvent-free

minimal surface preparation

easy implementation

applicable at all temperatures and hygrometries

COMPOSITION

TEDO Primer: Vaseline-based paste, solvent-free, applicable by hand or brush

KEBU Tape: Vaseline-based anti-corrosion tape, applicable by hand

KEBU PE 0.50 tape: tape based on butyl rubber and polyethylene, applicable by hand.

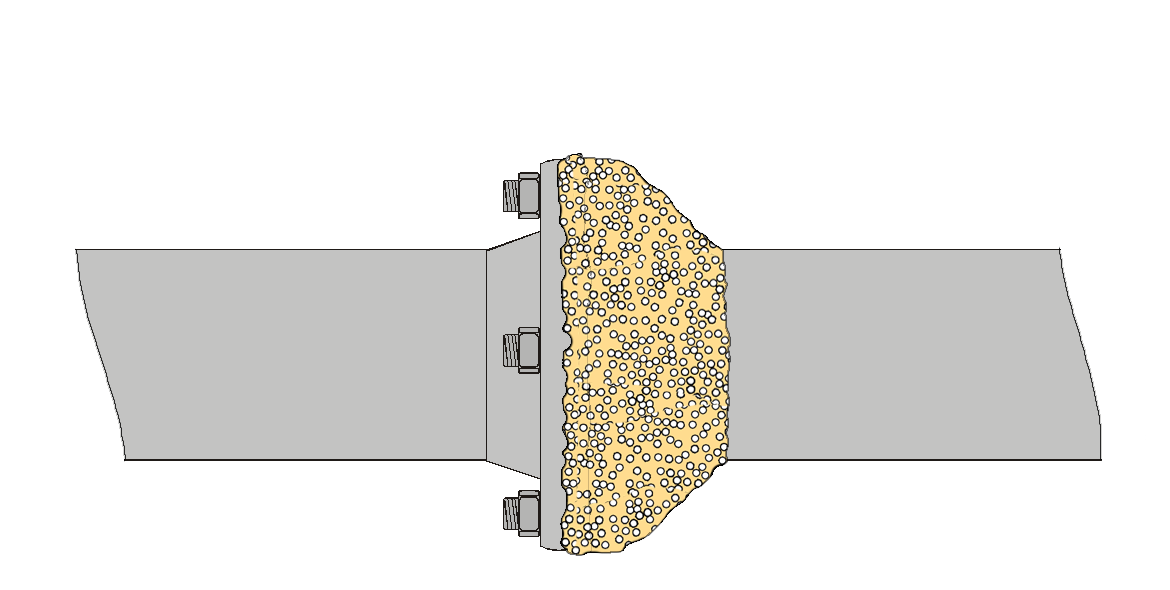

For filling voids and chamfers:

TEDO PFM: putty based on vaseline and polystyrene beads

The components of the TEDO PMB-01 system are not classified as hazardous products and can be stored without limitation over time, provided that the storage conditions are respected.

PRINCIPLES OF IMPLEMENTATION

Surface preparation

The surface can be cleaned by mechanical or manual brushing.

Care should be taken to remove old non-adherent coatings, dust and other dirt, non-adherent rust and generally any particles likely to end up between the surface of the metal and the coating system.

Step 1: Application of TEDO primer paste

The paste is applied by hand or with a brush, depending on its consistency, which depends on the temperature.

Step 2: Application of KEBU anti-corrosion tape

KEBU anti-corrosion tape is applied in a spiral, under slight tension (the tape is not elastic), with a minimum overlap of 50%.

Care should be taken to carefully smooth the strip after application, to eliminate any air bubbles and to close the coils properly.

Step 3: Application of KEBU PE 0.50 mechanical protection strip

The mechanical protection strip is applied under tension, with a 50% overlap. The start of the coating is done if possible slightly offset from the KEBU anti-corrosion strip.

KEBU PE 0.50 tape is flexible and easily applied by hand.

For shaped parts, use TEDO PFM putty to fill voids and round corners