Applications

STAMP spacer and centering collars allow:

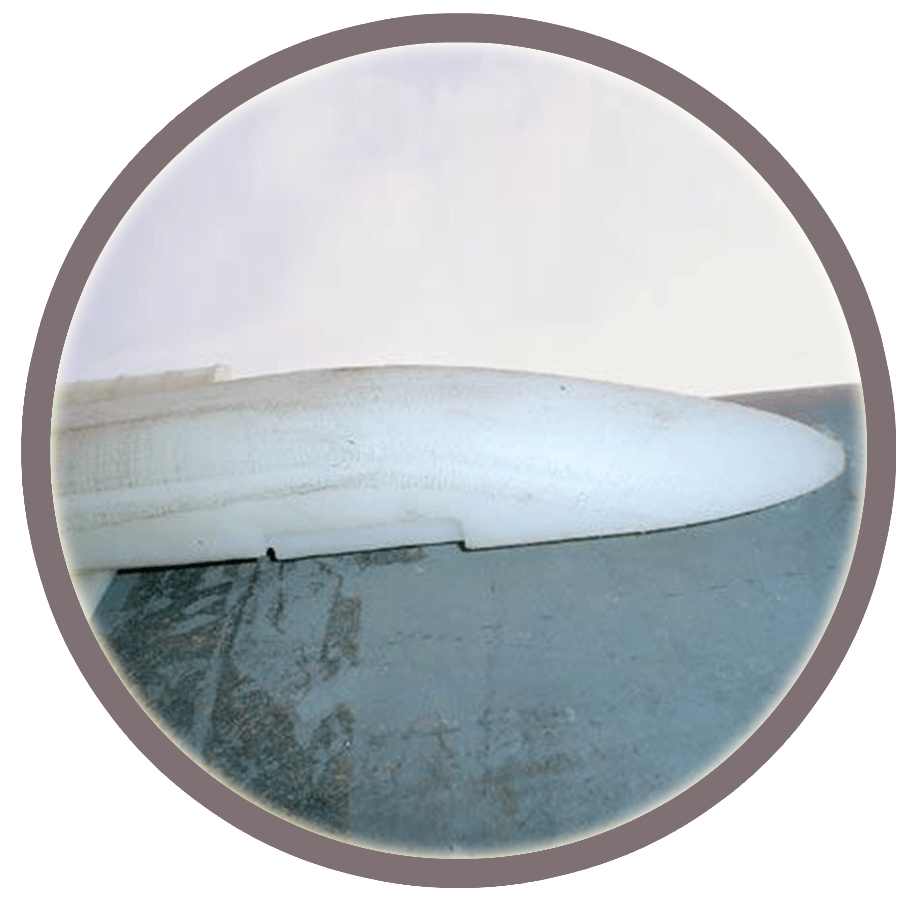

- to ensure electrical insulation of the pipe in the protective sheath

- to ensure that the pipe is threaded into the sheath without damaging the coating

- the installation of service pipes or cables along the entire length of the duct

- to withstand thermal and mechanical stresses, particularly during installation

Implementation

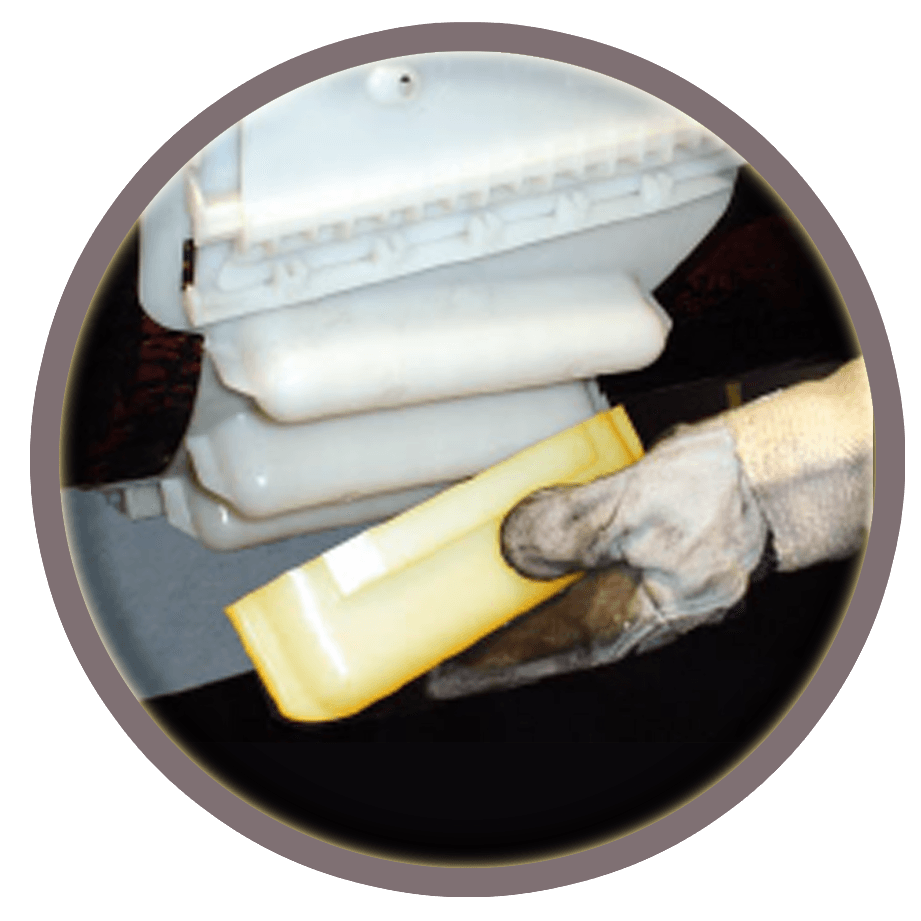

STAMP collars can be easily installed by hand using a hammer, without special tools, allowing for quick and economical implementation.

Guide to product selection

To determine the most suitable collar, the following data is required:

- outside diameter of the main pipe, including coating (mm).

- inner diameter of the sheath (mm).

- length of the crossing (m).

- materials making up the main pipe and the sheath.

(eg: in the case of a cast iron main pipe, the height of the collars must be sufficient to exceed the outer diameter of the socket by at least 10-15 mm, etc.)

- Fluid transported in the main line.

- Presence of other elements in the sheath (pipes, cables, etc.).

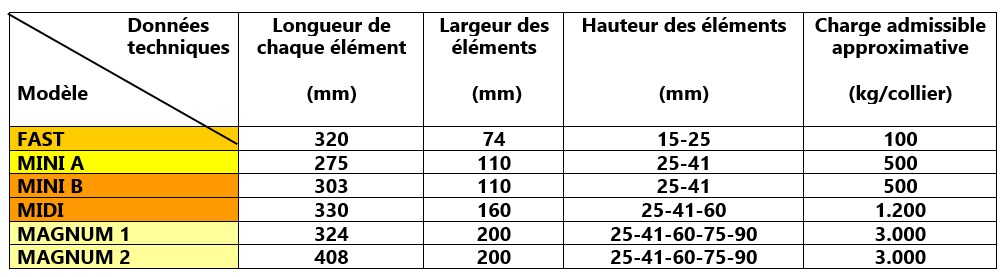

We then proceed to determine the type of collar, the number of elements to make up the collar and finally to calculate the number of elements required on the basis of the following tables:

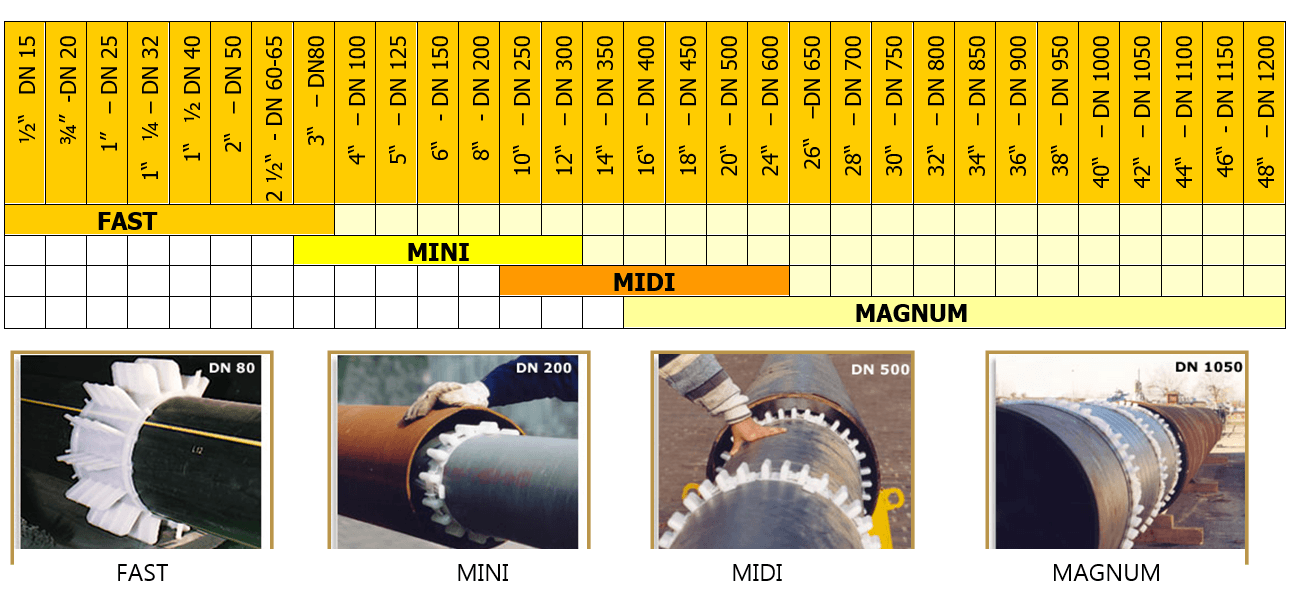

STAMP centering collars have been designed and manufactured to offer the best solution to each need / tube diameter. They are offered in three types:

- FAST model consisting of a strip that can be cut on site and fixed with plastic straps.

- MINI and MIDI models consisting of a spacer element and a longitudinal clamping wedge;

- MAGNUM model consisting of a spacer element and a trapezoidal locking wedge.

Determining the number of elements per necklace

Determining the total number of collars

Double clamp is recommended at each end of the pipeline to avoid insertion problems due to load distribution.

For a crossing of length (L), the number of collars for each crossing (N2) is calculated as follows:

N2 = L 3

I

Where (I) is the distance between 2 collars (usually 2 meters)

Dimensional characteristics

NOTICED

The value of the coefficient of friction and the average abrasion value depend on the material of the protective tube and are therefore communicated on request for each specific project.

Transport and storage

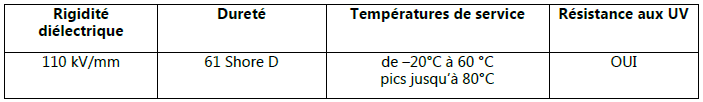

Notwithstanding the good UV resistance, it is recommended to keep the spacer collar elements in their cartons until use.

As for storage, no other special measures are required, given the rigidity of the material and the absence of an expiry date.

The production date and batch number are indicated on each item, to enable their traceability.

Installation

For standard crossings (length not exceeding 50 m), the application procedures described in the product assembly sheet apply (see IM002 a / b / c / d / e).

For crossings exceeding this value and/or particularly restrictive application and/or service conditions, please contact our sales office to assess, in the specific case, the most appropriate value of the center distance and/or particular means of application.

Accessories

EXTRA SHIELD

Abrasion protection

Extra Shield is a rigid element that can be inserted by pressure on the centering collar pads, without using glue or a metal part to fix it.

Its purpose is to provide additional abrasion resistance to the pads which directly support the load of the carrier tube.

It can be used as a "sacrificial element" in cases of very significant wear.

Extra Shield increases the load-bearing capacity of each collar from 20 kN (2000 kg) as standard to 35 kN (3500 kg).

Extra Shield for Magnum centering collar is available in different versions, which can be installed with different spacings.

XTENSION

Booster seat

Xtension is a rigid element that can be added to the skates to increase their height, without using glue or metal parts to fix it.

Xtension is used to raise the pipe in case of risk of infiltration, to reduce deformation during water hammer or to allow the installation of cables or other pipes.

EURO ROLLER

Euro roller is a rolling support composed of a steel structure, a composite material wheel and a steel fixing clamp.

Each Euro roller can support a weight of 5000 KG.

It is used to support the main pipe over a limited length during its insertion into the sheath.

Euro roller can be reused and does not require maintenance;